Creality Ender 3 S1 & Ender-3 S1 Pro Reviews / Reader Test: I’m Lars, 40 years old. Through Kristian’s contribution to the Anycubic I3 Mega, I got into 3D printing in 2018 and now I have five printers and a small sideline in this area. I got the chance to test the Creality Ender 3 S1 as a guest tester for China-Gadgets and of course I gladly accepted the offer. Here is my test report.

The Creality Ender 3 S1 is the new offshoot of the very popular Ender 3 series and the first with a direct extruder. With a price of €309, it is currently more affordable, but it is not one of the cheapest printers. Some of the Ender 3 V2 can be had for as little as €200. Let’s see if the S1 keeps what Creality promises.

Creality Ender 3 S1 Review

- Creality Ender-3 S1

- at Geekbuying for €239.65 – voucher NNNFRBES1 (incl. 1 kg filament ABS grey, pay with PayPal!)

- Activate a €40 coupon at Amazon for €333

- Creality Ender-3 S1 Pro

- at TOMTOP for €276 (DE warehouse) – voucher: ED6368

- at Geekbuying for €299.65 (EU warehouse) – Coupon: NNNCRCFS1PRO

- at Cafago for €299.99 – Coupon: CAC6368

- at Banggood for €585.68

- Creality Ender-3 S1 Plus

- at Geekbuying for €327.28 – Voucher: GKB11ANNI2 (Pay with PayPal!)

- at Cafago for €329.99 – coupon CS6551

- at TOMTOP for €358

- Specifications of the Creality Ender 3 S1

| Name | Creality Ender 3 S1 |

| print volume | 220 x 220 x 270mm |

| Printable Materials (Manufacturers) | PLA, TPU, PETG, ABS |

| Extruder | “Sprite” Direct Extruder |

| Filament | 1,75 mm |

| Weight | Package: 11.2 kg / device 9.2 kg |

| connections | USB-C, SD-Card |

| Extras | Automatic heatbed leveling “CR-Touch”, double Z-axis, synchronized belts, magnetic spring steel print bed, PC coated, belt tensioner on X and Y-axis |

Scope of delivery and packaging

The package came directly from TomTop and was with me within 3 days, that was really fast. The printer arrived well packaged. The box is stable and the printer is securely housed in several layers of foam.

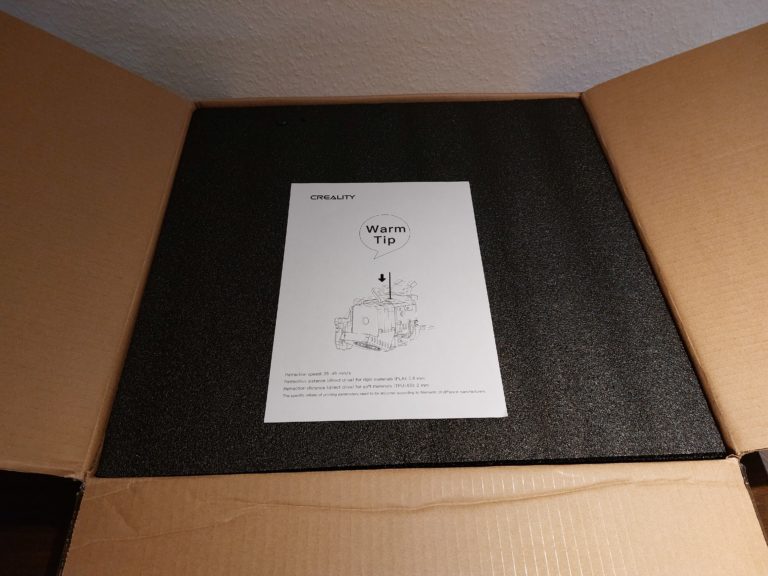

On top of that was a “warm tip” with a few tips on printing parameters. I like that.

The small parts of the printer were found under a foam layer, including the extruder, filament holder, IEC connector, etc. In the layer below is the Z-axis and the base.

Everything you need to get started is included as an accessory, of course in the simplest “China quality”:

- Fork Wrench

- Allen key

- spatula

- side cutters

- 1 replacement nozzle 0.4mm

- 1 Düsennadel

- SD card and USB adapter

- 1 end stop (more on that later)

- Printed instructions, also in German

- 1 small roll of filament

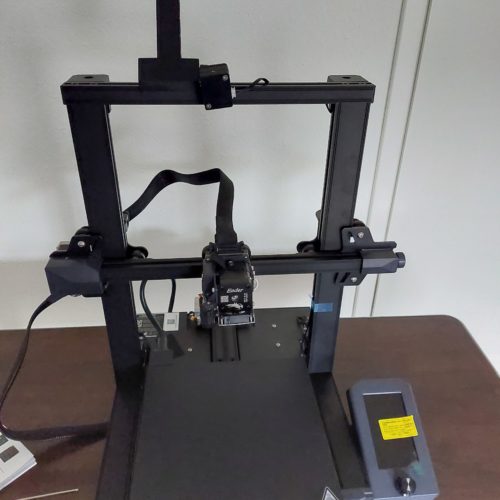

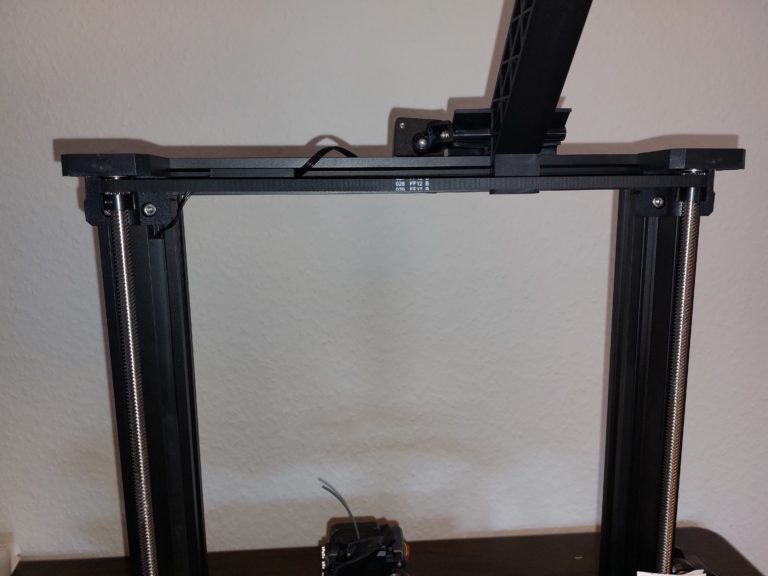

Construction: It couldn’t be simpler

The structure is very simple and is also well described in the instructions. The core printer consists of only 4 parts:

- Basis

- Z axis

- Extruder

- Display

The Z-axis is screwed onto the base with four screws. The angles were right for me, which wasn’t always the case with the Ender 3 models. Then the extruder is screwed to the carriage with four screws, the display holder is screwed on and the display is connected. The cables are connected to the plugs, confusion is almost impossible due to the very good labeling.

In general, one has to say that the cable management is super clean. The cables run almost completely in the profiles, nothing is reminiscent of the craft shops of the past (Anet A8 and Co.). The filament holder is attached together with the filament sensor to the crossbar of the Z-axis. What must still be done after assembly is the adjustment of the rollers of the X and Y axes.

With my previous printers, some of them were tightened too much, which caused damage to the rollers. With the Ender 3 S1, these are now very loose, so that both the print bed and the extruder carriage have noticeable playhad. This play can be adjusted with the supplied tool using an eccentric on the rollers. Very good in itself, because the roles remain intact. You just have to think about it, otherwise no printing is possible.

Build Quality

The processing quality is top. Everything feels high quality and stable. The holes fit and the angles of the Z-axis are correct too. The double Z-axis with belt synchronization prevents the axis from “hanging”, a real shortcoming with many Creality printers.

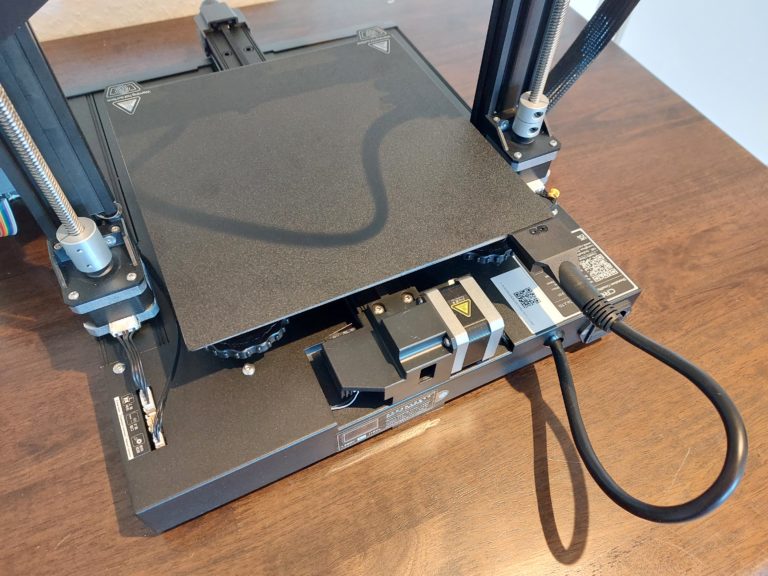

There are belt tensioners on the X and Y axes, which are always very welcome. There is a small drawer in the front, which is really very useful for storing the instructions and small parts. The USB-C and SD card slot are very user-friendly on the front.

The print bed is equipped with a magnet system. A PC-coated spring steel sheet is used as the print pad. The biggest advantage is that you can use other (magnetic) pads without modifications. The cable of the print bed has a strain relief, which definitely benefits the service life. Unfortunately, the print bed insulation is missing, which I would definitely recommend upgrading to reduce energy consumption.

The filament holder is attached to the top of the Z-axis together with the filament sensor. I think this is unfavorable, since the weight of a spool of filament can increase the Z-axis oscillation at higher pressures.

It is operated via a color display, which acts like a touch display, but is only controlled via the rotary pushbutton. Parameters such as temperatures, Z offset, fan speed, etc. can be changed during the printing process. It is intuitive to use and very useful. A touch display is not missing here.

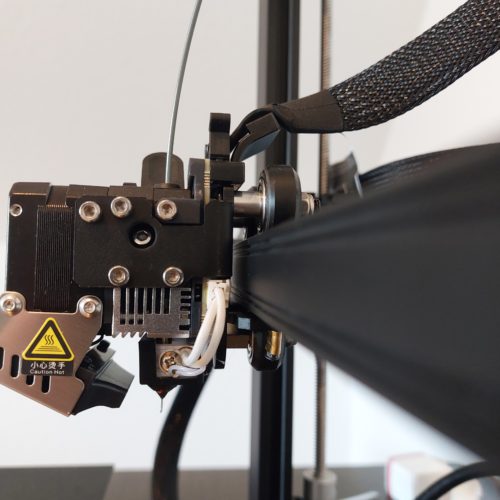

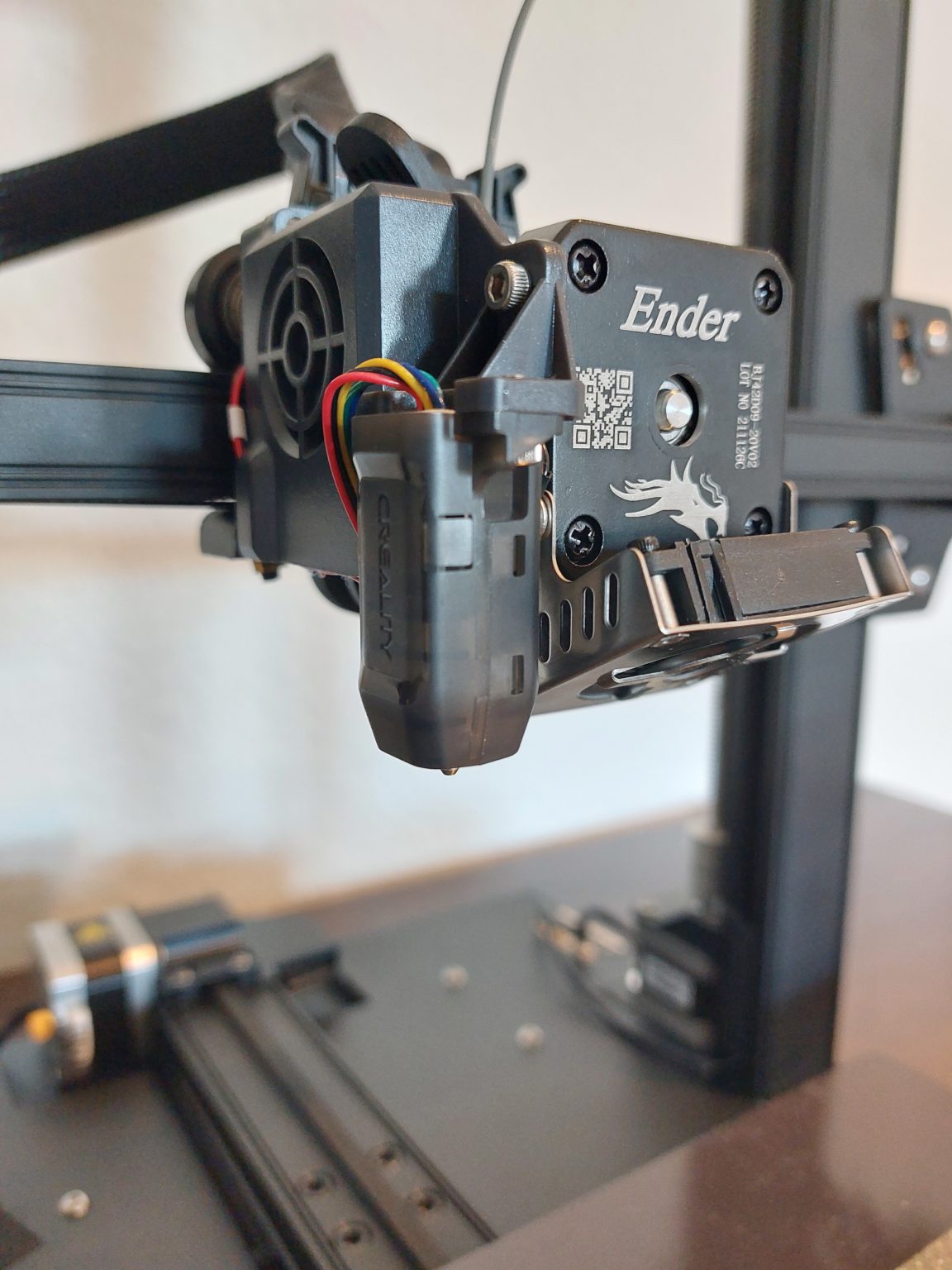

The extruder is an in-house development by Creality called “Sprite”. It is very compact and lightweight. This also means that the individual parts are not so easy to reach and swap. The component cooling is on one side and blocks the frontal view of the nozzle. You can see the print area well from the side.

The nozzles appear to be standard MK8 nozzles in thread and length as found on all Creality printers. In the outlet area, however, material has been removed and the wall thickness reduced. In my tests, I need 20-30°C higher printing temperatures than with other printers, which may be due to the thinner wall thickness of the nozzles in the outlet area in combination with the very strong component cooling.

Leveling

The Ender 3 S1 has a leveling system called “CR-Touch”. A sensor on the hotend, which works like a Z-endstop, measures 16 points on the heating bed and uses them to create a mesh grid that compensates for the unevenness of the printing bed during printing.

A classic Z-endstop is also included. For this you have to play but probably another firmware. For this reason we do not consider it here. Unlike what is described in the otherwise very good instructions, I first roughly level the bed with a sheet of paper and the adjusting screws and then carry out the auto-leveling. The procedure can be started at the push of a button and runs automatically.

With that we created the mesh. Then we have to set the distance between the nozzle and the heating bed at one point using the Z offset (well explained in the instructions) and the leveling is done. A weakness of this procedure is that the leveling is done with a cold nozzle and print bed.

Even if I heat up beforehand, both the bed heater and the jet heater turn off as soon as I start leveling. Normally, leveling is always done at the working temperature of the nozzle and the bed, as there can be different distances due to the different expansion of the materials of the print bed and the extruder.

Nevertheless, it works perfectly and the distances are correct.

Print Results

The first thing I do when I unpack a printer: I put the original filament far away. For the first tests, I always use filament that I know for sure works. So I can rule out the filament as a source of error if something goes wrong. The gray and red filament from M4P was used for my PLA tests. I would by no means describe the volume of the printer as quiet, although silent drivers are installed, the fans – as usual – make quite a noise, especially the hot end cooler, which is only 3 cm in size. For an office it is clearly too loud for me.

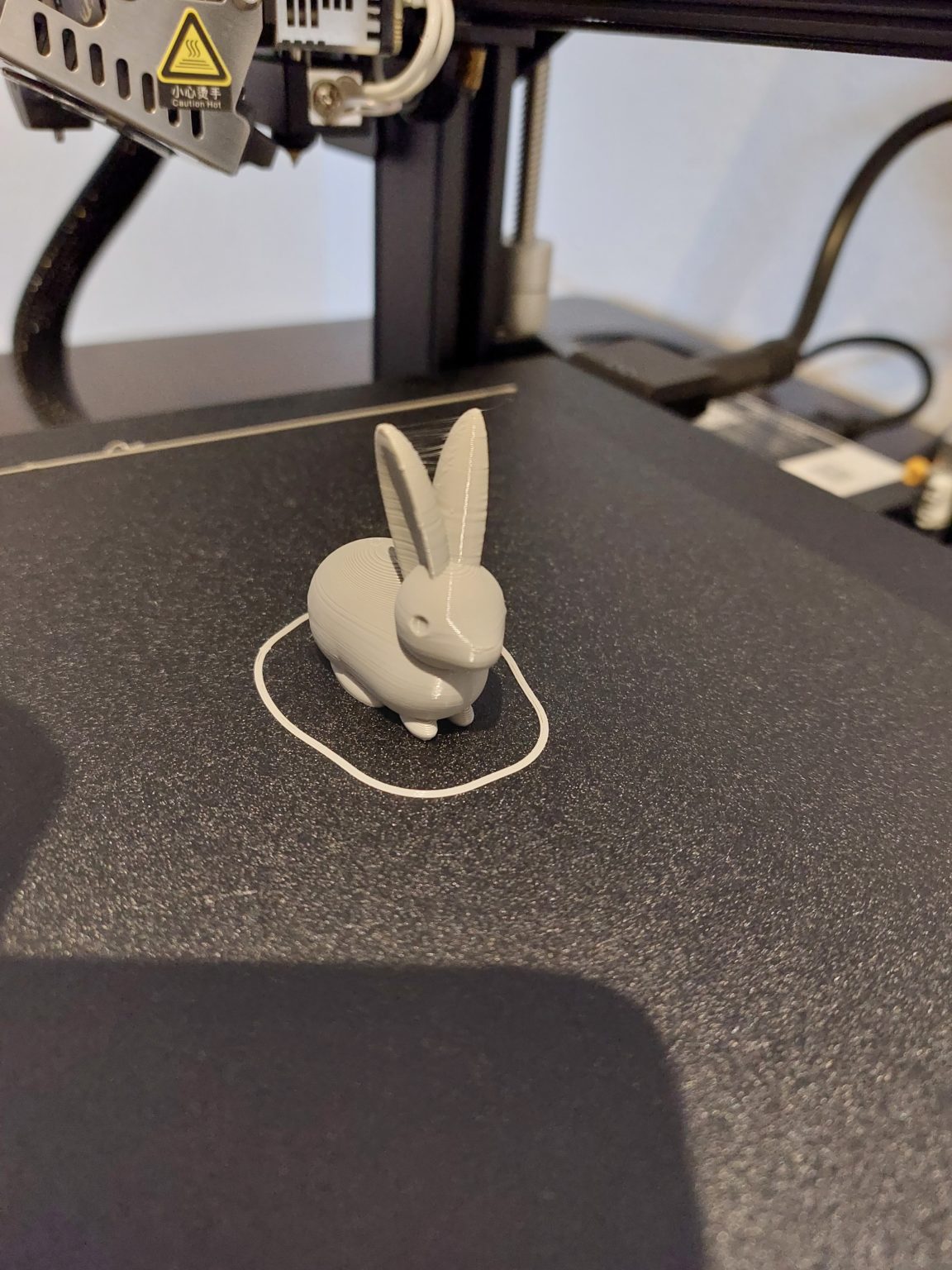

First I printed the rabbit that can be found pre-sliced on the SD card to get an impression of whether the printer itself is working correctly. After the part printed very well, I decided to split this chapter into a beginner part and an advanced part.

Beginner

In this test I examined out of the box quality, which is important for a complete beginner. I wanted to use the Creality Slicer from the supplied SD card, but I couldn’t install it and it stopped with an error message. I then downloaded it from the Creality site, installed it and accepted the stored profile without any changes and determined the optimal printing temperature with a temperature tower ( 3D printer: the perfect temperature for hotend & hotbed ). After that I printed a Benchy with these settings.

I have to say that I have never seen such a good out of the box result from any printer before. Unfortunately, the Z-seam setting in the Creality Slicer apparently has a bug, which is why the Z-seam prevents a better result. We still have some stringing, but overall a good result.

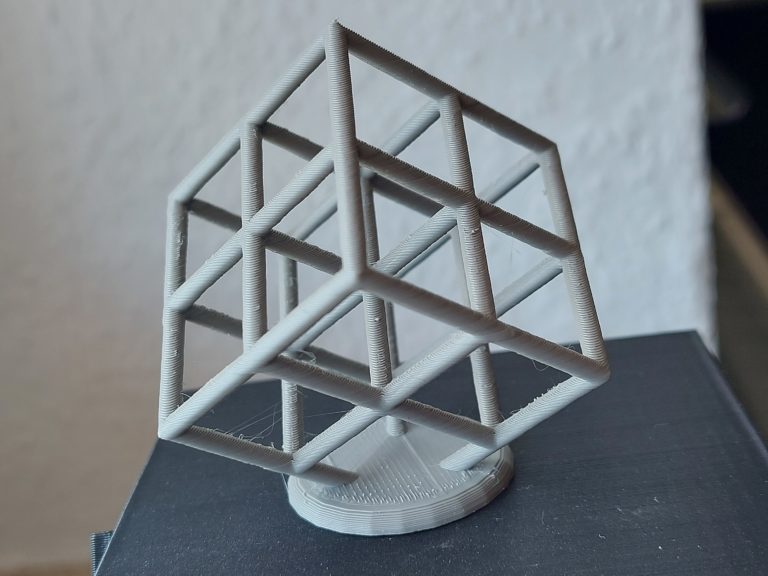

Next, I chose the Lattice Cube as an endurance test. An endurance test for component cooling and a large number of retracts. We have a bit more stringing and a slightly unclean printed side facing away from the fan, but still good quality.

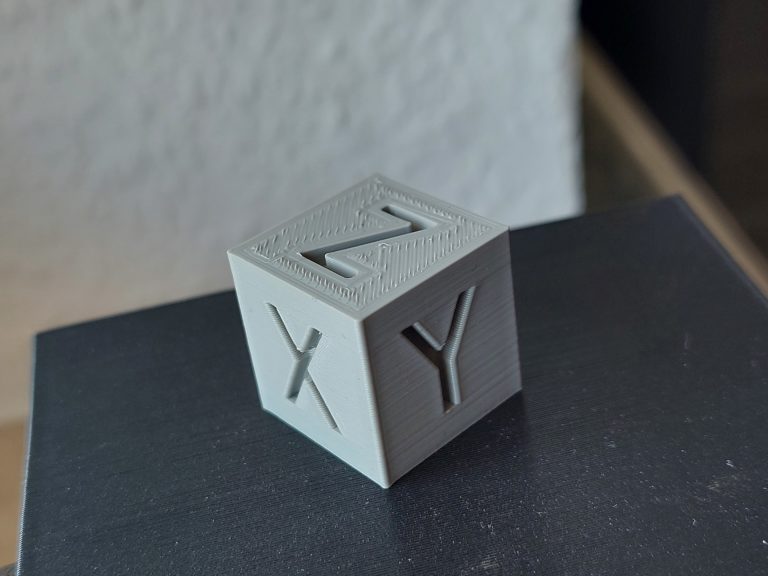

The calibration cube also looks good and measures 20.1 x 20.2 x 20.05 mm (target: 20mm). The surface suggests an overextrusion, which can explain the slightly larger dimensions and also the stringing in the previous tests.

Without any modification to the print profile, the quality is already very good. The gray used is a test filament, which reveals every little mistake, so there is nothing to complain about there. Out of the box, the printer is already able to get you started with 3D printing without frustration. From this basis, you can optimize the result.

Advanced

After the printer was already impressive without changing the settings, I wanted to test what else could be achieved with the usual setting options without changing the hardware. I only had to change one thing, the print bed support. I can’t get along with the PC-coated spring steel sheet.

The adhesion is far too strong and if I level it up a little bit, the first layer is no longer closed. Without further ado, I ordered a rough PEI-coated spring steel plate, which can also be found ex works on the Ender 3 S1 Pro. This means you are also prepared for ASA, for example.

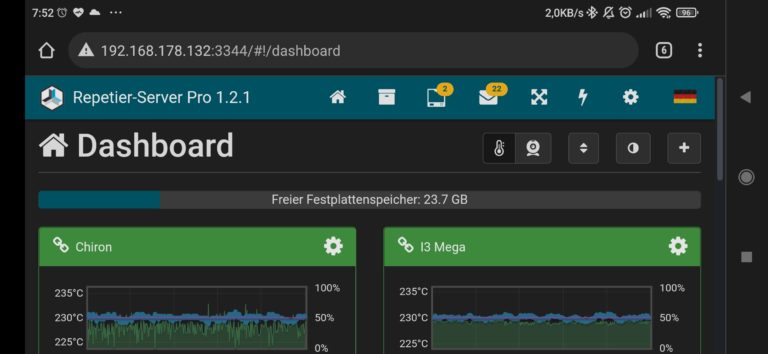

The integration into a print server, in my case Repetier Server, worked without any problems. This is important for me because I can start and monitor the prints directly from the computer.

I was very positively surprised that in addition to the hotend, the heating bed is also PID controlled. A good part of the good print quality out of the box comes from that. In addition, no PID tuning was necessary because the temperatures were very stable.

In addition, I built a profile in Cura, because Cura can set the Z-seam correctly. I tried to find the optimal parameters by means of a temperature tower, retract tests and adjustment of the material flow. The result is a benchy and lattice cube of even better quality.

As an absolute endurance test, I printed a Voronoi-style cat to push the printer to its limits and it turned out very well too. Very light stringing can still be seen here and there. Some optimization is certainly still possible, but some printers do not even manage to print these fine and complex structures in a durable manner.

Anyone who has already dealt with TPU knows that it is not easy to print. The stringing in particular is difficult to get a grip on. The S1 with a direct extruder should be able to handle this well. The result is really impressive. The Benchy is printed very cleanly and almost free of stringing, well done Creality.

Conclusion: For beginners and advanced users?

The Creality Ender 3 S1 is not a cheap 3D printer when you look at the competition, that’s clear. But I have to say that the good out-of-the-box quality and the frustration-free entry into the 3D printing world must be countered. If you just want to print without a lot of tinkering, this printer is the right choice for you. I will definitely recommend it to beginners without any restrictions.

Advanced

I also find the package offered very good for advanced users. The extruder does its job really well, the magnetic print bed system is very flexible and customizable. All things that you have to retrofit, sometimes expensive. I think it’s so good that it will probably become THE new printer for my finer things and my TPU prints. He has earned his place with me.

Pros

- Direct extruder

- Magnetic heating bed pad on spring steel

- Good workmanship

- Good quality out of the box

- Dual Z axis

- Heated bed PID controlled

- Working autolevelling

Cons

- Not exactly cheap

- “Only” PC instead of PEI coated print bed overlay

- Leveling takes place in the cold state

- No heated bed insulation